Academic Express | Energy examination and optimization workflow for container farms: A case study in Shanghai, China

Recently, a team led by Associate Professor Dayi Lai and Assistant Professor Jiao Xue from the School of Design at Shanghai Jiao Tong University published an academic paper titled "Energy examination and optimization workflow for container farms: A case study in Shanghai, China" in Applied Energy (IF=10.1, JCR Q1). This study utilized building physics methods to establish and validate an energy consumption prediction model for the environmental control system of containerized plant factories. Besides, this study proposed a comprehensive energy-saving design and operational management strategy for plant factories that combines active (air conditioning + mechanical ventilation) and passive (container envelope) methods.

Abstract

Container farm (CF) is a promising method to satisfy the urban vegetable demand and achieve global climate goals. Vegetable growth in fully artificial interior environments enables an efficient, steady, and year-round production of vegetables despite outdoor climate conditions. However, the high energy intensity associated with CF remains a bottleneck for its generalization. To minimize the energy consumption of container farms (CFs), this study conducted a detailed energy examination and proposed an energy optimization workflow. In the energy examination, an energy model was developed based on the lumped parameter method using EnergyPlus and validated by two benchmark experiments on a specific CF on Chongming Island, Shanghai. The results revealed that the predicted energy consumption was consistent with the measured energy consumption: the normalized mean bias error (NMBE) was <1%, and the coefficient of variation of the root-mean-square error (CV(RMSE)) was <25% for the hourly air-conditioning energy. With the validated energy model, energy optimization was considered in the hot period and other period, tailored to the local climate and characteristics of the equipment in the target CF. Based on parallel computing, the optimal envelope design was determined by enumeration in the hot period, whereas the optimal mechanical ventilation schedule was obtained by the selection-after-subdivision method in the other period. The maximal energy-saving potential of the two-period workflow was 773.4 kWh, which accounted for 33.8% of the original air-conditioning energy use, i.e. 25% more saving than the non-staged method. This study provides suggestions for the CF energy examination and support CF design improvements and operation decision-making. The examination process and optimization workflow can be extended to energy savings in other indoor agricultural methods.

Keywords: Container plant factory, Building energy simulation, Multivariate optimization, Mechanical ventilation, Two-period optimization

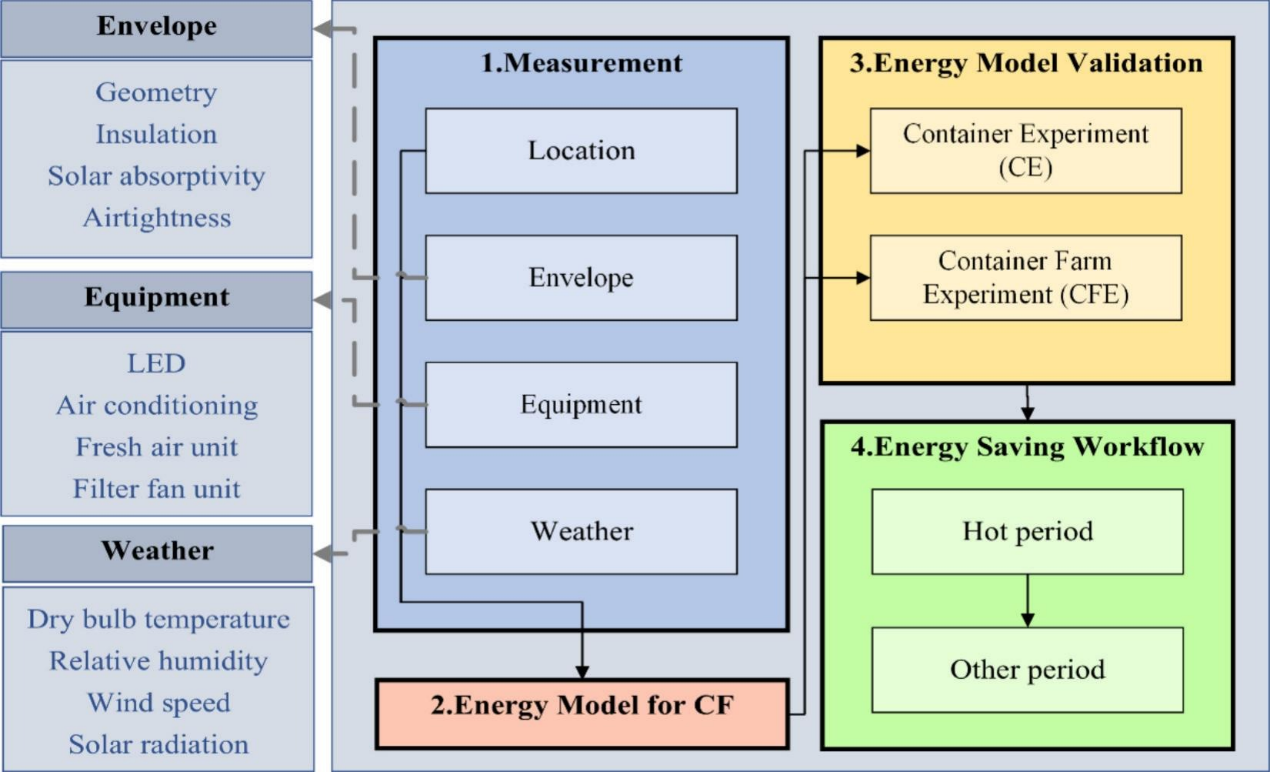

Overall framework of the energy examination and energy optimization

Interior layout of the 20-foot CF in this study

Predicted hourly A/C energy usage versus measured hourly A/C energy usage

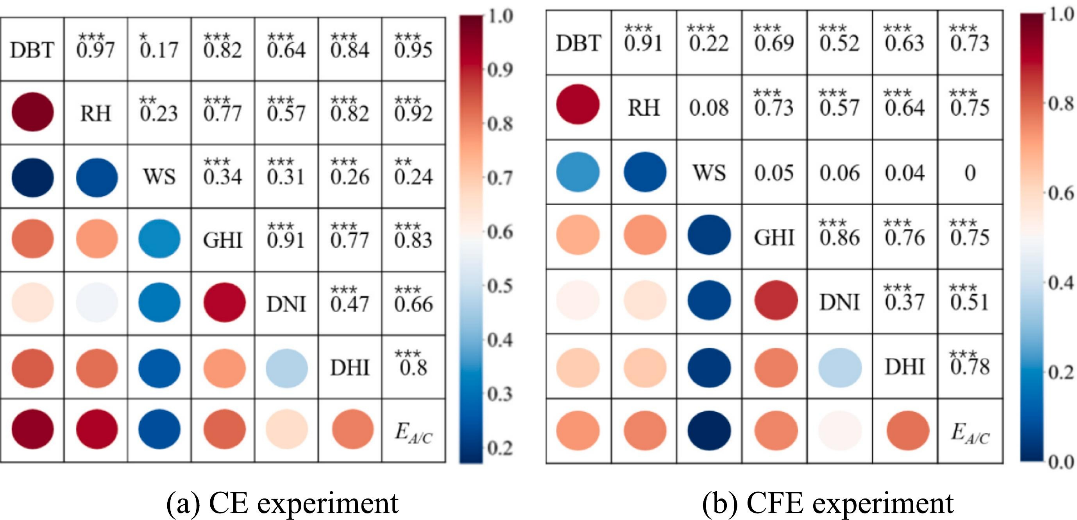

Correlation between climatic factors and hourly A/C energy usage

This study was funded by the Science and Technology Commission of Shanghai Municipality (23Z510201924). This study was conducted in collaboration with Professor Jingjin Zhang's team from the School of Agriculture and Biology at Shanghai Jiao Tong University, Professor Hua Bao's team from the Global Institute of Future Technology at Shanghai Jiao Tong University, and Bright Seedbase (Shanghai) Technology Co., Ltd, Shanghai, China.