设计学报·技术 | 利用建筑物理方法优化植物工厂环控系统能耗

近日,上海交通大学设计学院设计学博士研究生俞之桐以第一作者身份,在高水平国际期刊《Applied Energy》(影响因子10.1,JCR/Q1,中科院SCI一区,Top期刊)上发表了学术论文“Energy examination and optimization workflow for container farms: A case study in Shanghai, China”。该论文在设计学院建筑学系副教授赖达祎及设计系助理教授薛娇指导下完成。该研究利用建筑物理方法,建立和验证了集装箱式植物工厂环控系统的能耗预测模型,并提出了主动(空调+机械通风)和被动(围护结构)结合的植物工厂综合节能设计和运行管理策略。

论文摘要

集装箱植物工厂(Container Farm,CF)可以在完全人工控制的室内环境中培育作物,完成高效、稳定、不受外部气候条件影响的全年生产,是满足城市农业需求并实现全球气候目标的重要手段。然而,高能耗是制约集装箱式植物工厂推广的瓶颈。为降低集装箱式植物工厂的能耗,本研究对集装箱式植物工厂进行了详细的能源分析,并提出了一种环控系统能耗优化流程。

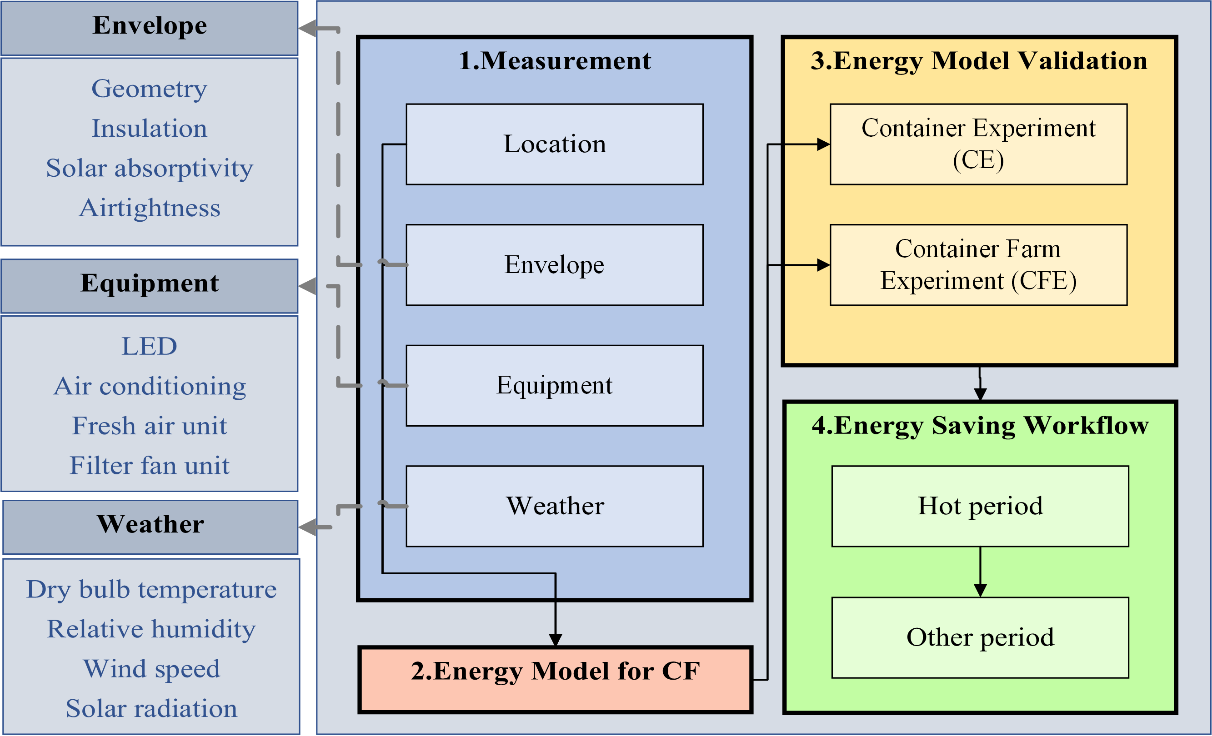

在能源分析中,基于集中参数法和 EnergyPlus 开发了集装箱式植物工厂运行能耗模型,并通过在上海崇明岛上进行的两项基准实验对能耗模型进行了验证。结果表明,预测的能耗与实际测量的能耗一致:逐小时空调能耗计算的归一化平均偏差误差(NMBE)小于 1%,而根均方误差的变化系数(CV(RMSE))小于 25%。在经验证的能耗模型基础上,研究根据目标集装箱植物工厂的气候和设备特性,制定了分别考虑热期和非热期的两期能耗优化流程。基于并行计算,在热期通过枚举法确定了最优的围护结构设计,而在其他期间通过选择后细分方法获得了最优的机械通风计划。两期优化流程的最大节能潜力为 773.4 kWh,占原空调能耗的 33.8%,比传统的不分阶段方法多节能25%。

本研究提供了集装箱植物工厂能耗优化的建议,以及集装箱植物工厂设计改进和运营管理决策。该分析方法和优化流程可以推广到其他室内农业的节能研究中。

关键词:集装箱式植物工厂,建筑能效模拟,多变量优化,机械通风,两期优化。

Abstract

Container farm (CF) is a promising method to satisfy the urban vegetable demand and achieve global climate goals. Vegetable growth in fully artificial interior environments enables an efficient, steady, and year-round production of vegetables despite outdoor climate conditions. However, the high energy intensity associated with CF remains a bottleneck for its generalization. To minimize the energy consumption of container farms (CFs), this study conducted a detailed energy examination and proposed an energy optimization workflow. In the energy examination, an energy model was developed based on the lumped parameter method using EnergyPlus and validated by two benchmark experiments on a specific CF on Chongming Island, Shanghai. The results revealed that the predicted energy consumption was consistent with the measured energy consumption: the normalized mean bias error (NMBE) was less than 1 %, and the coefficient of variation of the root-mean-square error (CV(RMSE)) was less than 25 % for the hourly air-conditioning energy. With the validated energy model, energy optimization was considered in the hot period and other period, tailored to the local climate and characteristics of the equipment in the target CF. Based on parallel computing, the optimal envelope design was determined by enumeration in the hot period, whereas the optimal mechanical ventilation schedule was obtained by the selection-after-subdivision method in the other period. The maximal energy-saving potential of the two-period workflow was 773.4 kWh, which accounted for 33.8 % of the original air-conditioning energy use, i.e. 25 % more saving than the non-staged method. This study provides suggestions for the CF energy examination and support CF design improvements and operation decision-making. The examination process and optimization workflow can be extended to energy savings in other indoor agricultural methods.

Keywords: Container plant factory, Building energy simulation, Multivariate optimization, Mechanical ventilation, Two-period optimization.

集装箱式植物工厂能耗审查和优化的总体研究框架

集装箱植物工厂内部布置

采用机械通风策略前后植物工厂空调能耗对比

遗传算法确定最优围护结构设计

采用机械通风策略前后植物工厂空调能耗对比

与传统不区分阶段优化的节能潜力对比

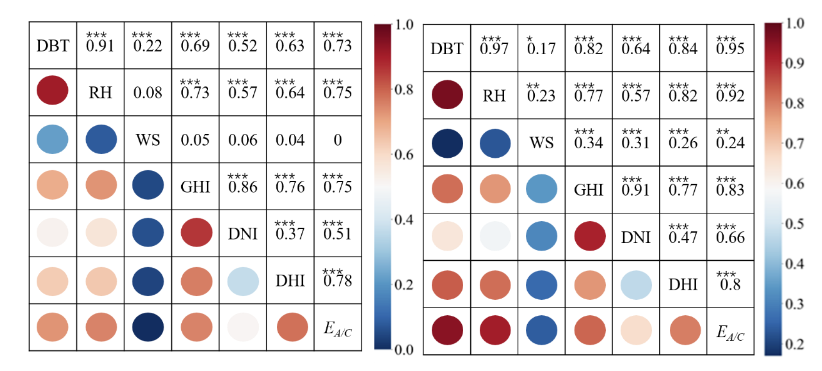

气候参数对植物工厂运行能耗的影响及显著性分析

本研究得到上海市科委科技创新行动计划/农业项目(23Z510201924)资助。本研究与上海交通大学农业与生物学院章竞瑾副研究员团队、上海交通大学未来技术学院鲍华教授团队、上海光明母港(上海)种业科技有限公司合作完成。